Poplar Series

Overview

Description

Specifications

Brochures & Resources

[ paused ]

The POPLAR air separation plant produces liquid oxygen, liquid nitrogen, and, as an option, liquid argon suitable for all industrial sectors, including medical applications. Nikkiso Cosmodyne’s nearly 50 years of experience with cryogenic plants is reflected in the design and durability of the POPLAR series.

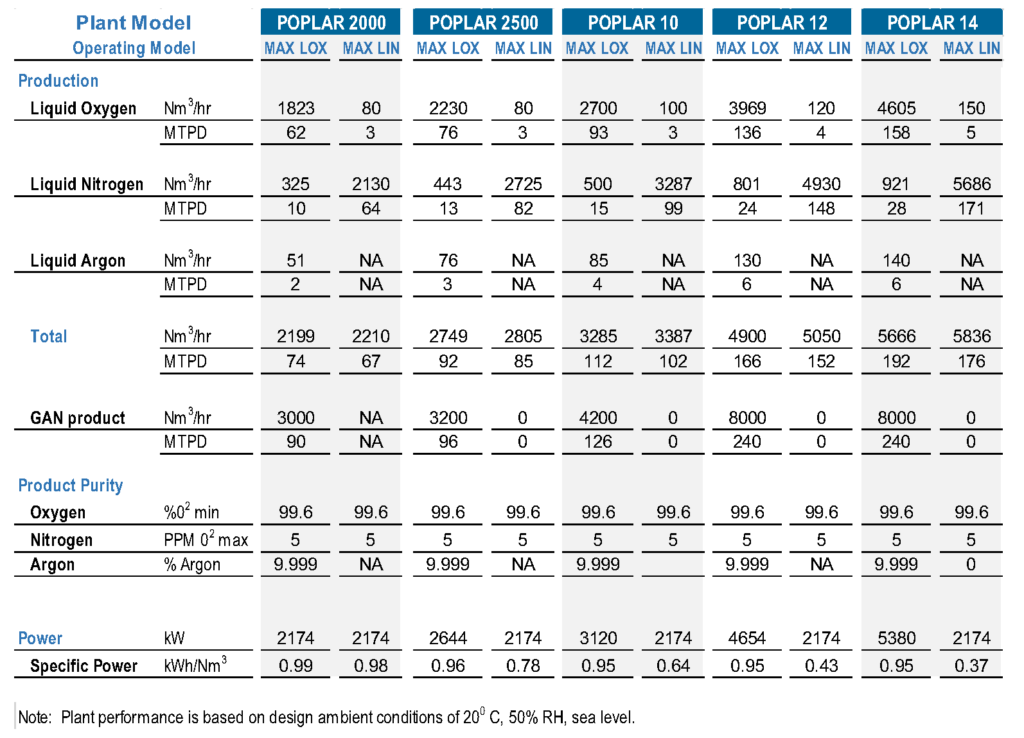

Capacities range from just over 40 metric tons per day to 200 tons per day of total liquid product. The plants have been designed to provide the lowest specific power, as low as 0.89 kw-hr/Nm³. The POPLAR plant is designed to minimize shipping and allow for rapid installation by providing the plant in seven distinct, pre-piped and pre-wired modules: cold box, turbo-expander, air chiller, heater skid and adsorber vessels.

Features & Benefits

- Nikkiso Cosmodyne PLC based control system provides efficient, user-friendly graphic interface for remote, local or unattended operation

- Automatic control of all primary plant functions

- State-of-the-art analytical instrumentation package

- Dual, high performance turbo-compressors with removable cartridge style rotating elements

- Proven molecular sieve type air clean-up system

- Turboexpander and cryogenic equipment are designed and built in-house

- Crude Argon Production

- Refined Liquid Argon Production

- Nitrogen Liquefier – ELM Series

- Closed Loop Evaporative Cooling System

- 50 or 60 Hertz Electrical System

- Product Storage Tanks

- Cylinder Charging Systems

- Liquid Transfer Pump Systems

- Other customized features for site specific requirements

Applications

- Air Separation

- Medical

- Manufacturing

Services

- On-site or in-factory operator training

- Installation and commissioning assistance

- Extended warranty package

- Service package

- Aftermarket spare parts support

- Aftermarket technical support

Specifications

- Nm³ specified at 0°C, 1.013 bara

- Plant performance is based on standard atmospheric conditions (ambient temperature 20°C, relative humidity 50%, cooling water temperature 19°C, 1.0 atm barometric pressure)

- Specific power excludes cooling water power.

Cosmodyne POPLAR Series

Cosmodyne POPLAR Series Poplar 1500 commissioned in EL Salvador

Poplar 1500 commissioned in EL Salvador Cosmodyne expands Poplar merchant plant

Cosmodyne expands Poplar merchant plant