Aspen Series

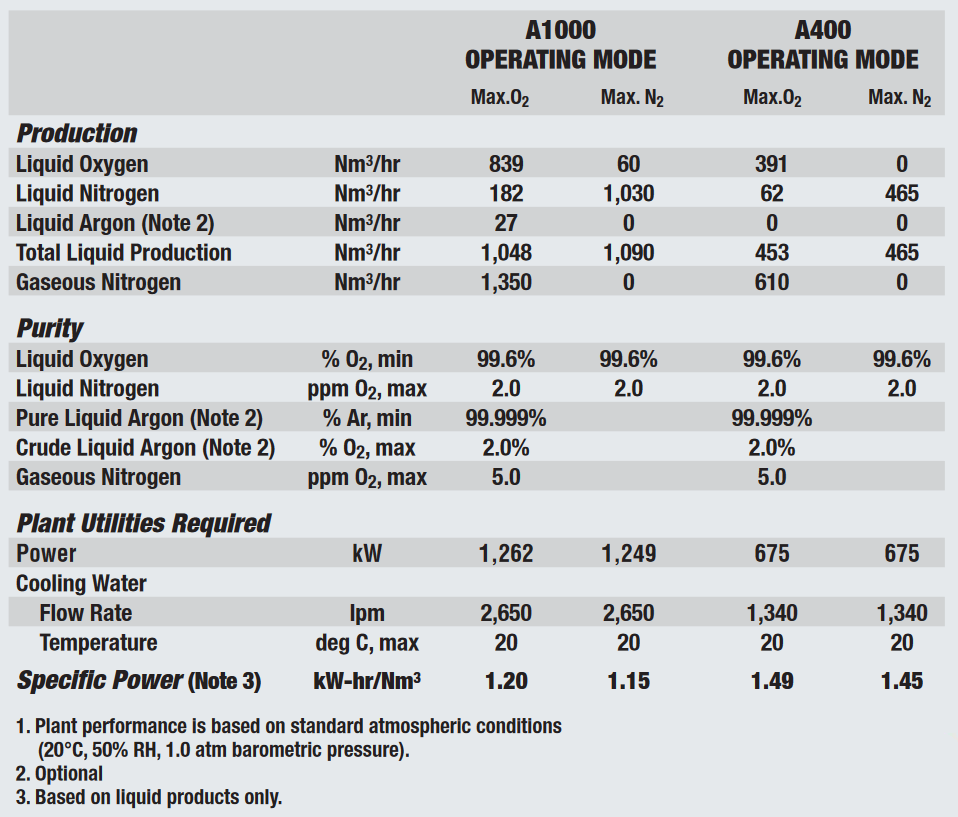

The ASPEN plant is a medium sized air separation plant designed to produce liquid nitrogen, oxygen and, as an option, liquid argon by cryogenic distillation of atmospheric air. In addition, when operating in maximum oxygen mode, gaseous nitrogen is also available, if required, when there is a pipeline or other on-site nitrogen requirement or to liquefy for additional liquid nitrogen capacity. Capacities range from 15 to 35 metric tons per day. The ASPEN plant is designed to minimize shipping and allow for rapid installation by providing the plant in four distinct modules: the main air compressor, the air treatment module, the recycle compressor, and the cold box. The plant system is self-contained and can be completely installed outdoors. The plants require a source of cooling water, power supply and a simple foundation.

The ASPEN plants are designed to meet the most severe operating conditions. Over 35 ASPEN plants have been deployed producing liquid oxygen, nitrogen and argon for medical, industrial, oil field and military applications in some of the most remote regions of the world.

Features & Benefits

- The ASPEN plant can be run in liquid-assist mode to provide the owner some flexibility during times of low nitrogen demand or high power prices.

- Nikkiso Cosmodyne PLC based controls provides a user-friendly graphic interface for remote, local or unattended operation

- Automatic control of all primary plant functions

- State-of-the-art analytical instrumentation package

- Dual, high performance turboexpanders with removable cartridge style rotating elements

- Proven molecular sieve type air clean-up system

- Crude Argon Production

- Refined Liquid Argon Production

- Nitrogen Liquefier

- Closed Loop Evaporative Cooling System

- 50 or 60 Hertz Electrical System

- Product Storage Tanks

- Cylinder Charging Systems

- Liquid Transfer Pump Systems

- Other customized features for site specific requirements

Applications

- Air Separation

- Medical

- Industrial

- Manufacturing

- Packaging

Services

- On-site or in-factory operator training

- Installation and commissioning assistance

- Extended warranty package

- Service package

- Aftermarket spare parts support

- Aftermarket technical support

Cosmodyne ASPEN Series

Cosmodyne ASPEN Series Cosmodyne's ASPEN 1000 air separation plant - short lead time

Cosmodyne's ASPEN 1000 air separation plant - short lead time Cosmodyne broadens its range with the ASPEN 2000

Cosmodyne broadens its range with the ASPEN 2000 First move of ASPEN plant ends in success

First move of ASPEN plant ends in success Cosmodyne's ASPEN 1000 Racks Up Frequent Flier Miles

Cosmodyne's ASPEN 1000 Racks Up Frequent Flier Miles