ELM Liquefiers

Nitrogen Liquefiers provide sub-cooled liquid nitrogen from gaseous nitrogen feed gas for the many applications that use liquid nitrogen. Our Nitrogen Liquefiers are designed to provide you with liquid nitrogen from any clean and dry gaseous nitrogen source. Typically from the overhead nitrogen stream from an air separation plant (ASU) that would otherwise be vented.

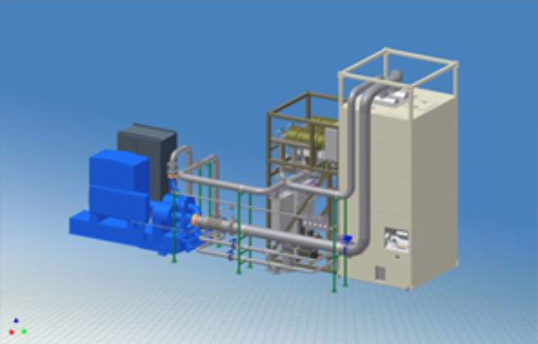

Our modular Nitrogen Liquefaction Plants can be configured to specific needs, such as liquefying an oxygen gas stream or simultaneous liquefaction of oxygen and nitrogen gas streams. Flow rate, pressure, and purity level are all completely adjustable. These are equipped with single or dual Nikkiso Cosmodyne turboexpanders (> 500 Nm³/hr).

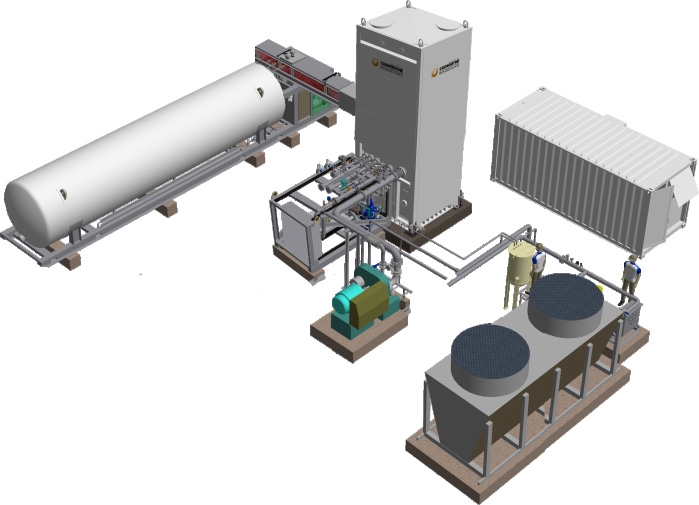

Ideal for emerging markets and remote locations, the ELM plants’ efficiency makes it equally suitable for more long-term production applications. The ELM Liquefiers allow conversion of a gas supply from an existing plant to liquid for storage. The gas can be supplied from a pipeline or vent gas off a PSA or Air Separation plant. The liquefier can also be used to recover flash gas in storage tanks. This innovative plant is built to meet the highest industrial gas safety and quality standards to ensure flawless and reliable performance under the most severe operating conditions.

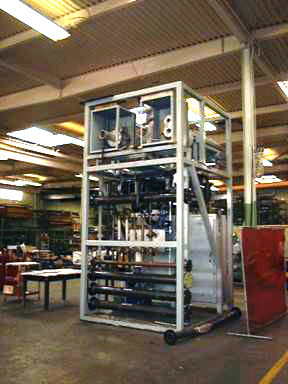

The ELM plant is designed to minimize shipping and allow for rapid installation by providing the plant in distinct pre-piped, pre-wired modules. The plant system is self-contained and can be completely installed outdoors.

Features & Benefits

- Efficient, reliable, and cost-effective solutions

- Modular design is shippable via container

- Allows conversion of gas supply from existing plant to liquid for storage

- Gas can be supplied from a pipeline or vent gas off a PSA or Air Separation plant

- Use to recover flash gas in storage tanks

- Meets the highest industrial gas safety and quality standards

- Structurally ideal for emerging markets and remote locations

- Suitable for more long-term production applications.

- Oxygen and Argon Liquefiers have independent Nitrogen refrigeration loop

- Oxygen liquefier can make both Liquid N2 and Oxygen in any split

- Plant system is self-contained – can be completely installed outdoors

- ELM FG minimizes cost by ensuring a liquid backup supply for an onsite PSA N₂ gas supply

- High-performance ACD low bearing loss roller element bearing turboexpander

- Cartridge-style rotating element for easy removal and installation

- Roller element bearings allow excellent loss-of-power protection for rundown: ideal for unreliable power

- Efficient, reliable oil free centrifugal or dry screw compressors

- Ships as three standard ISO containers to minimize transportation expense

- Complete with all interconnecting piping and electrical systems, ready for installation

- State-of-the-art control system

- Designed to allow unattended night shift operation, remote optimization, problem solving

- Remote start-up as well as un-attended startup

- Siemens S7 PLC Fully automatic digital process-control system with PC Based HMI with touch screen

- Choice of 50 or 60 Hz power systems

- CE compliant

- Dual product options available

- Factory cold performance Test

- ISO container Control Room

- Integrated product storage, high pressure pumping and transfer system

- Air cooled, evaporative water cooled or dry glycol cooling tower cooled

Applications

- Medical

- Manufacturing

- Packaging

Food Grade Nitrogen Gas and Liquid Nitrogen

- The new benchmark for food grade liquid and gas NITROGEN production.

- The ELM FG plants are designed specifically to meet the challenge of ever-increasing global power and fuel costs while maintaining the high reliability and mobility of a modular design that are container shippable.

- This innovative plant is built to meet the highest industrial gas safety and quality standards to ensure flawless and reliable performance under the most severe operating conditions.

- Structurally ideal for emerging markets and remote locations, the Elm FG plants phenomenal efficiency makes it equally suitable for more long-term production applications.

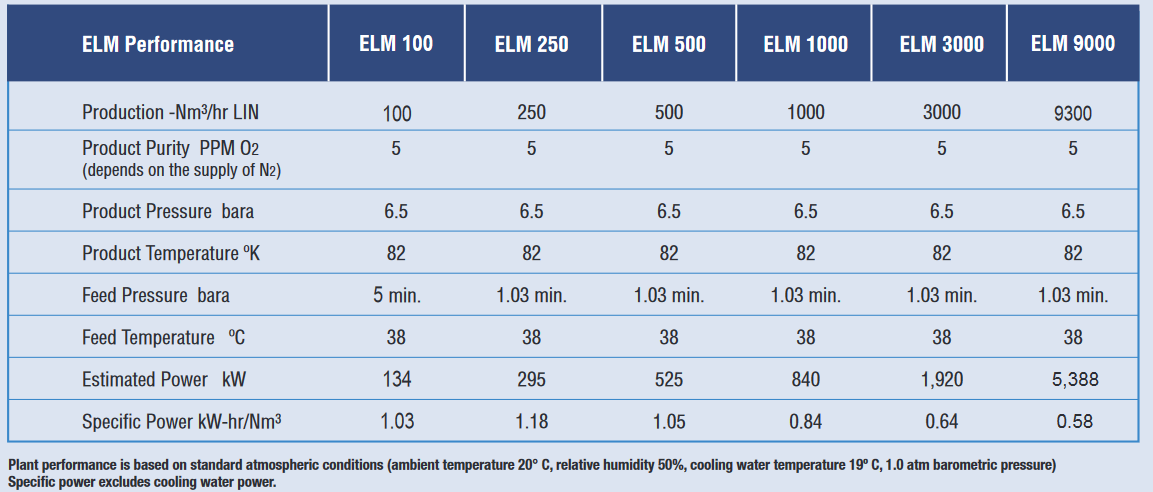

Specifications

ELM 30 to 300 Performance Table

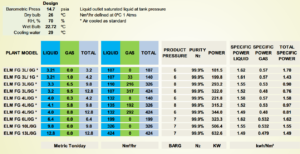

ELM FG Performance Table

Features & Benefits

- Plant performance is based on standard atmospheric conditions (ambient temperature 26°C, relative humidity 70%, cooling water temperature 29°C, 1.0 atm barometric pressure)

- Specific power excludes cooling water power

- Multiple different split modes are possible

- Oxygen/argon liquefier can also produce N2 liquid in any split mode

- Nm³ defined at 0°C, 14.7 psia

- Capacities from 3 to 300 tons

Production ranges from 150 to 10,000 Nm³/hr

Designed to produce N₂ with a maximum purity limit of 99.999% N₂

Cosmodyne ELM Series

Cosmodyne ELM Series ELM Series Liquefiers

ELM Series Liquefiers Elm Tank Farm and Options

Elm Tank Farm and Options ELM FG Tank Farm and Options

ELM FG Tank Farm and Options Cosmodyne Liquefiers answer demand for liquid production from existing gaseous sources

Cosmodyne Liquefiers answer demand for liquid production from existing gaseous sources Purchasing small to medium size merchant air separation plants

Purchasing small to medium size merchant air separation plants