Brands

Nikkiso Cosmodyne

For over 50 years Nikkiso Cosmodyne has been proud to be a leading supplier of Cryogenic Process plants. Our quality line of products includes Natural Gas Liquefiers (LNG), Air Separation Plants (liquid oxygen, nitrogen and argon) Nitrogen Generators (liquid and gas) and Industrial Gas Liquefiers.

Specializations

- Rotating equipment performance and mechanical test

- Systems Engineering

- Electrical Engineering

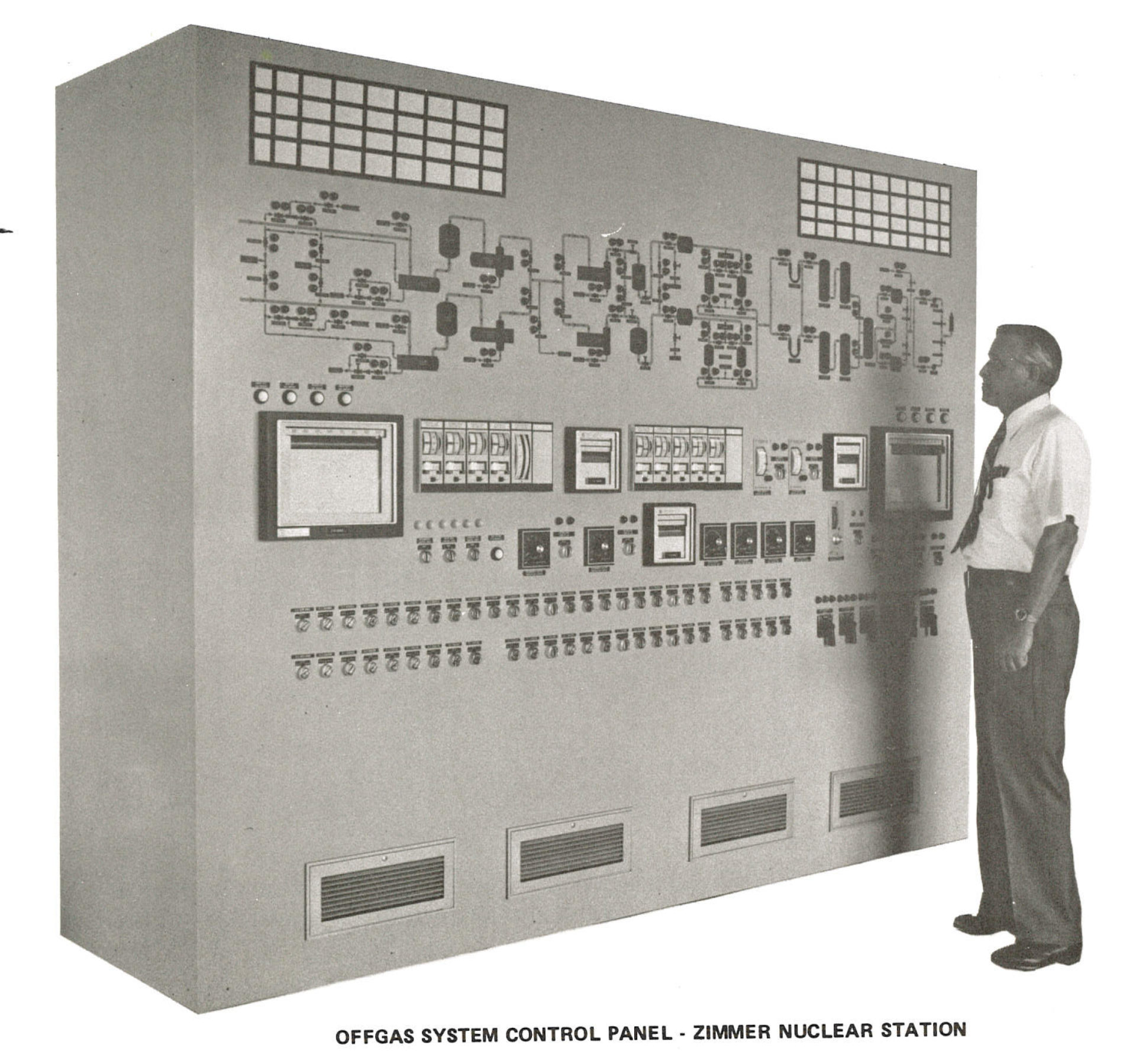

- Instrumentation and Control

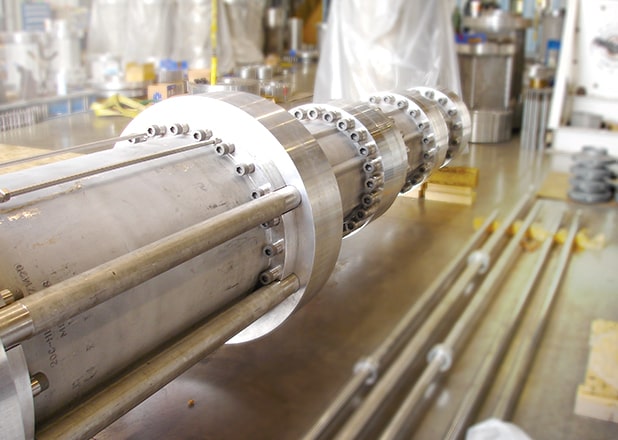

- Pressure Vessels and Piping

- Structural Engineering

- Fluid mechanics and Heat Transfer

About the Company

Nikkiso Cosmodyne is a leading provider of cryogenic process plants including industrial gas plants and natural gas liquefiers. Our natural gas liquefiers range in size from 5,000 to 500,000 gallons per day and can be scaled to meet a client’s specific requirements. Our industrial gas plants include an extensive range of air separation plants, nitrogen liquefiers and nitrogen gas plants which range in size from 4 to 300 metric tons per day.

Nikkiso Cosmodyne natural gas liquefiers serve various energy markets including alternative fuels for rail, trucks and marine and peak shaving applications. Our air separation plants serve the commercial industrial gas and oil field exploration businesses. All our plants are designed and manufactured in our California facilities. Manufacturing is completed in a state-of-the-art facility located in Murrieta, California, where there is over 30,000 m2 (320,000 square feet) of manufacturing space.

Nikkiso Cosmodyne is proud to back our stated performance with guarantees that are proven during a performance test conducted at the client’s site. The compact size, portability, ease of transportation and rapid on-site installation make our plants ideal to fulfill our client’s needs throughout the world. Each system is designed and built to rigorous standards of quality and workmanship developed from more than 40 years of specific experience. We are staffed by an innovative and experienced group of technical professionals.

Our History

Nikkiso Cosmodyne began as a small military contractor specializing in the handling and storage of complex fluids.The company’s earliest line of cryogenic products included pumps, vaporizers, subcoolers, valves, and storage vessels.

Nikkiso Cosmodyne then entered the commercial industrial gas market with air separation plants of approximately 4 Tons/day and grew its product line to today’s 300 Tons/day liquefaction capability. Most recently, with the development of LNG as an alternative fuel, Nikkiso Cosmodyne has applied its extensive liquefaction know-how to develop a line of natural gas liquefaction plants.

Nikkiso Cosmodyne has delivered plants to every continent and has become a key supplier to the major industrial gas companies, utilities and alternative fuels suppliers.

Engineering & Design

Each Nikkiso Cosmodyne plant is built to the highest standards of reliability and efficiency.

Nikkiso Cosmodyne’s state-of-the-art process simulation software ensures optimized plant performance and maximum process design flexibility. Our 3D mechanical design modeling software provides functional packaging, piping flexibility and static/dynamic analysis to produces modular plants designed for ease of shipment and rapid installation on site.

The controls system package includes the operator’s console, the control logic equipment and the instrumentation. The major components include PLC control and a functional, friendly HMI design that allows for unattended and remote operation of the plant.

Performance Testing

With every plant we manufacture, at a minimum, Nikkiso Cosmodyne conducts the following tests on its equipment: