Centrifugal Pumps

AC-32

Overview

Description

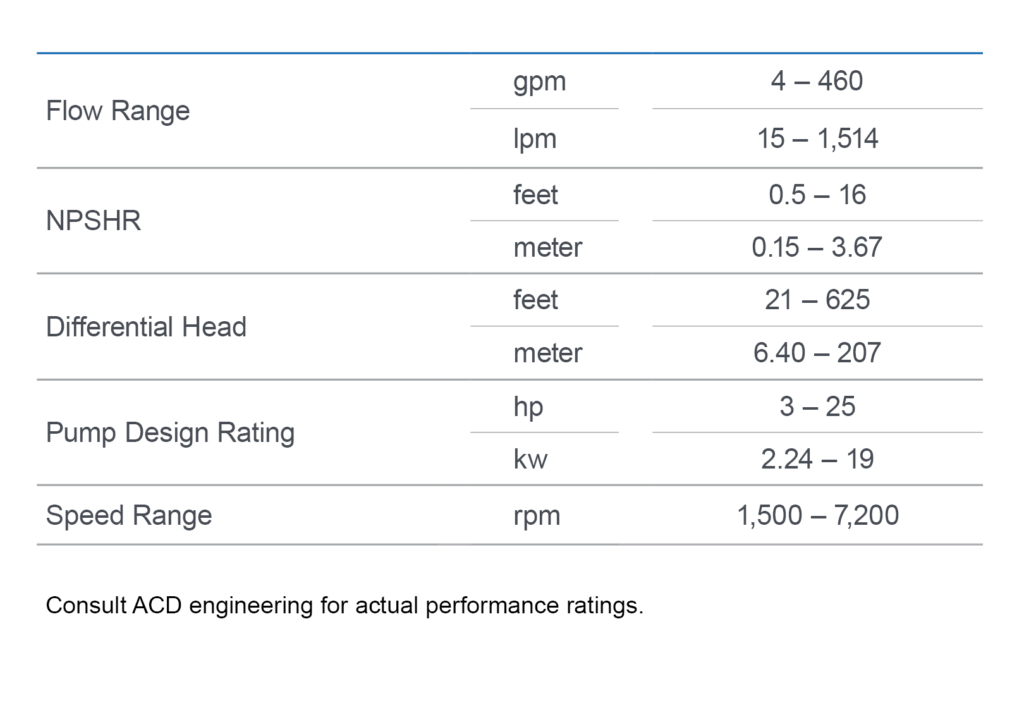

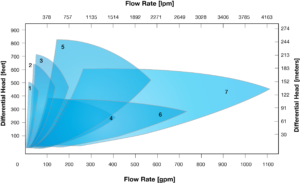

Specifications

[ paused ]

Marine

Fueling

High Horsepower

Terminal

Peak Shaving

Major Gas Companies

Independent Gas Companies

End Users

Virtual Pipeline

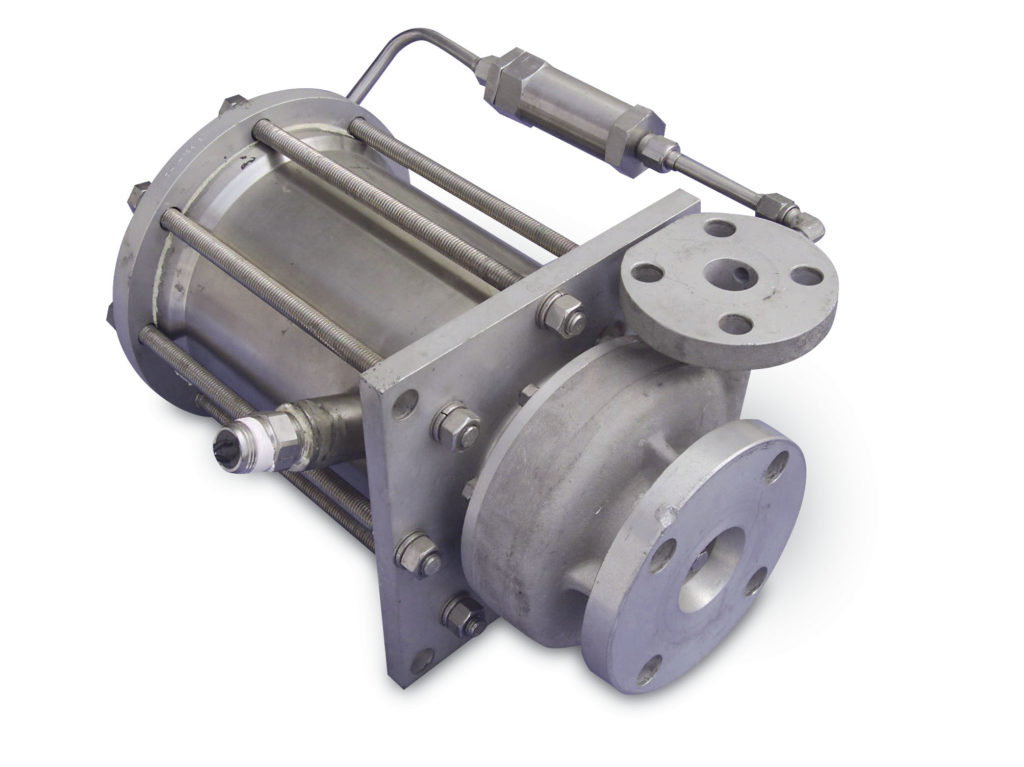

Our AC-32 pump assembly is a vertically oriented, single-stage, close coupled pump and is mounted directly on the drive motor. It is designed to be flooded with the liquid being pumped. No sump is required for operation. The bearings are cooled and lubricated by the fluid being pumped. Also, the inducer provides quicker and more reliable priming. The motor is specifically designed for Variable Frequency Drive. A VFD allows the pump speed to be tailored to the specific service, thus providing the best efficiency.

Features & Benefits

- Minimal start-up and downtime with guaranteed quick, responsive pumping

- No mechanical seal – minimizes maintenance costs

- No sump required – lowers the cost

- Multi-frequency motor provides an efficient, broad range of operation & power

- Electrical motor and bearing life is extended by being cooled by the cryogen it is pumping. Heat input is minimal and carried off by the discharging liquid

- Low NPSH inducer coupled with variable speed soft start motor eliminates cavitation at pump start-up

- Zero-leakage design is environmentally safe, releasing no volatile organic chemicals or contaminants (VOC’s) into the atmosphere

Applications

- Liquid Storage transfer

- LNG

- Fuel Loading

- Storage Tank Refilling

- Pipeline

- Peak-shaving

Liquids Pumped

- Nitrogen

- Argon

- Ethane

- Ethylene (C2H2)

- Methane (LNG)