Reciprocating Pumps

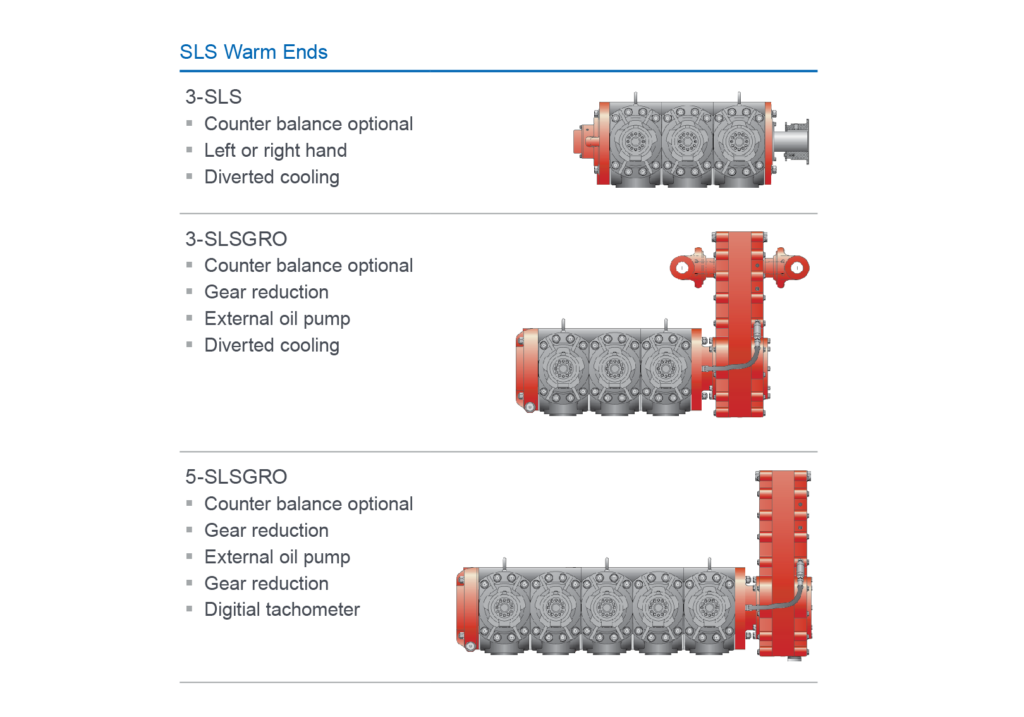

SLS

High Horsepower

End Users

Major Gas Companies

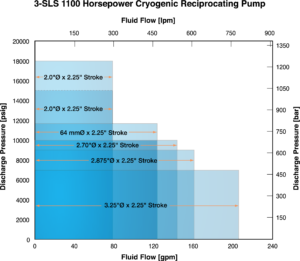

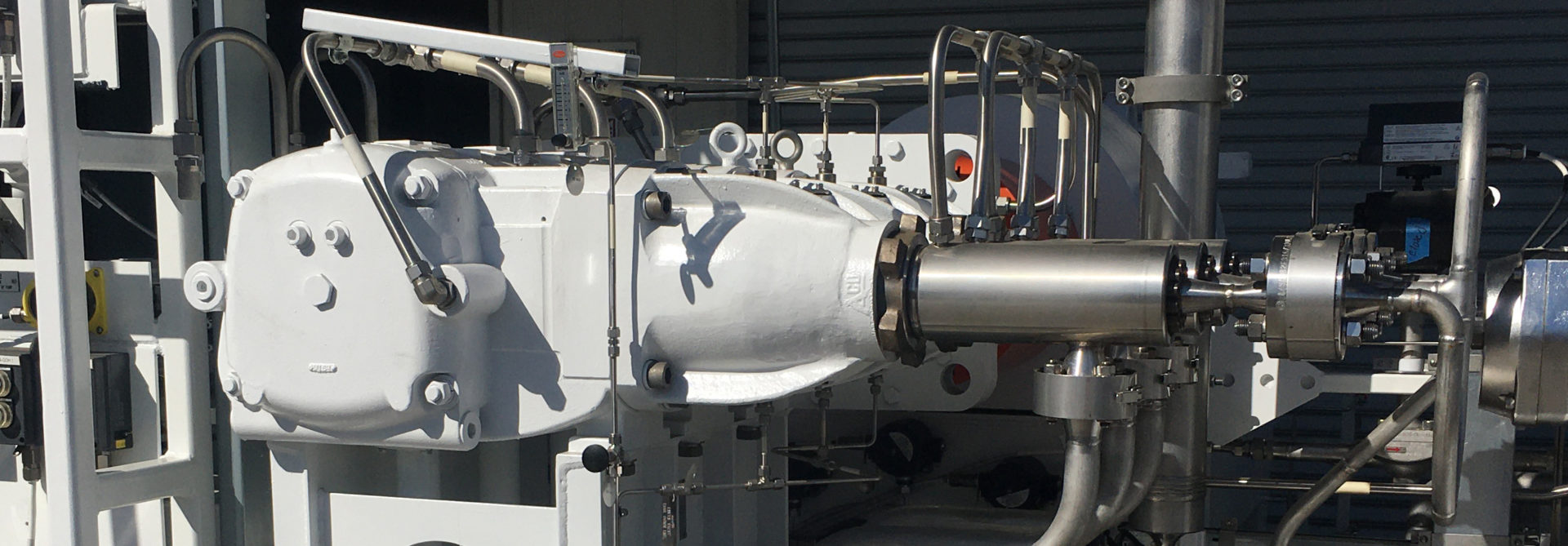

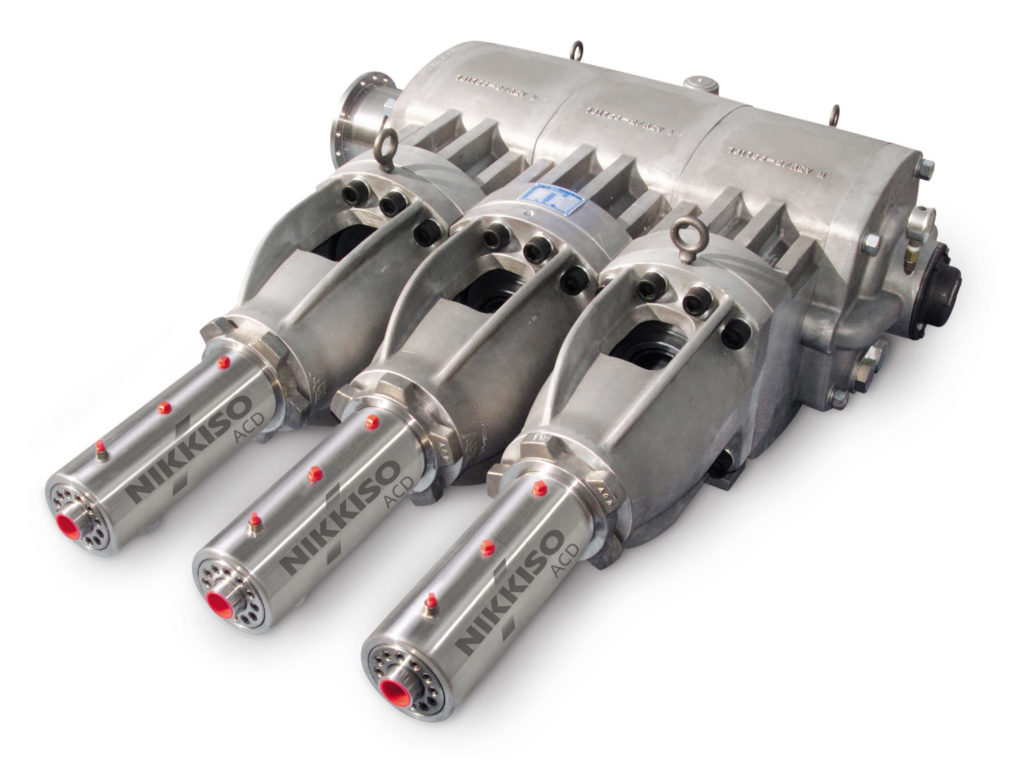

The SLS pump is a high flow, high pressure unit designed for the specific rigors of Enhanced Oil Recovery applications. It features a robust, forced fed oil lubricated drive that is constructed of heavy duty aluminum crank housings and intermediates, hard anodized crosshead pistons, heat treated alloy steel crankshaft and eccentrics, industrial strength ductile iron connecting rods, and robust babbitted bearings for extended product life and reliability of power end. The drive is available in a 3 or 5 cylinder configuration for a variety of flow ranges and comes equipped with digital tachometer port. The drive is coupled to a selection of 6 sizes of heavy duty high pressure cold ends that are designed for maximum strength and durability while optimizing mass distribution to achieve rapid cool down.

Features & Benefits

- Improved drive end design allows for longer life and cooler temperatures during operation

- Multiple configurations enable adaptability and conformity to mobile and/or stationary applications using a standard base model

- Better than 30-to-one turndown ratios allows for a wide range of operating parameters, including low enough flows to meet coil-tubing applications

- Non-Key Polygon Design reduces drive end failure risk due to shaft key

- Delicate operations such as furnace bake-outs, catalyst regeneration and hydrocarbon and solvent stripping have been safely performed using high temperature inert

Applications

- Oil Well

- Mobile Pumping

- 2 Purging

- High pressure Systems

Liquids Pumped

- Ethylene

- Methane

- Nitrogen

Typical Scope of Supply

- Nitrogen purging using Nikkiso ACD pumps is a technique used to replace hydrocarbon vapors, flammable and toxic gases or air with an environmentally safe and inert dry atmosphere. The two most common methods of purging are displacement and dilution. The geometry of the process system determines which method is used. For simple systems, displacement purging is usually more effective in terms.