Reciprocating Pumps

SGV

Hydrogen

Fueling

High Horsepower

Independent Gas Companies

End Users

Major Gas Companies

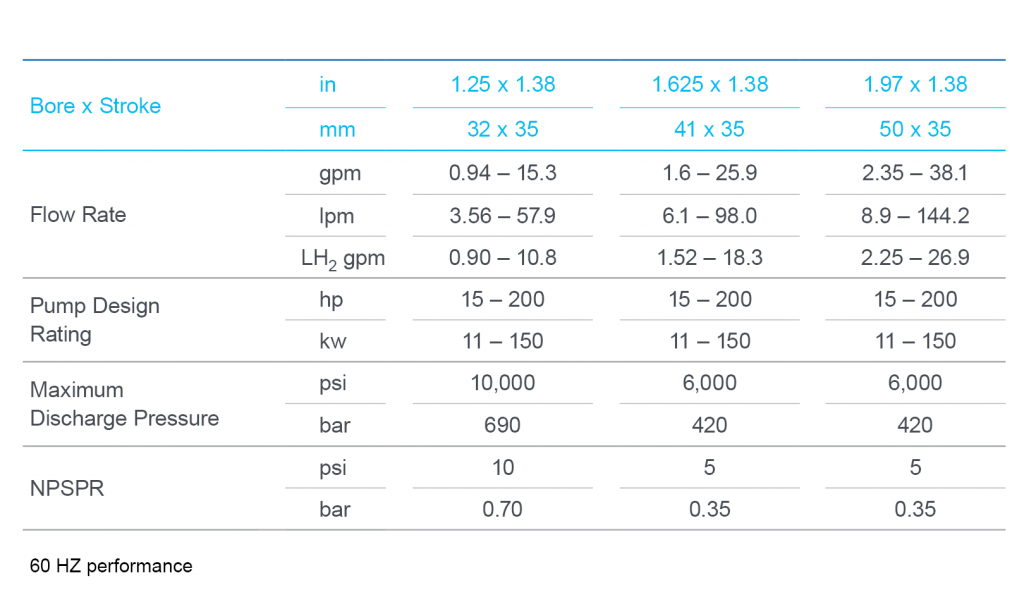

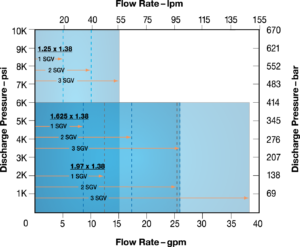

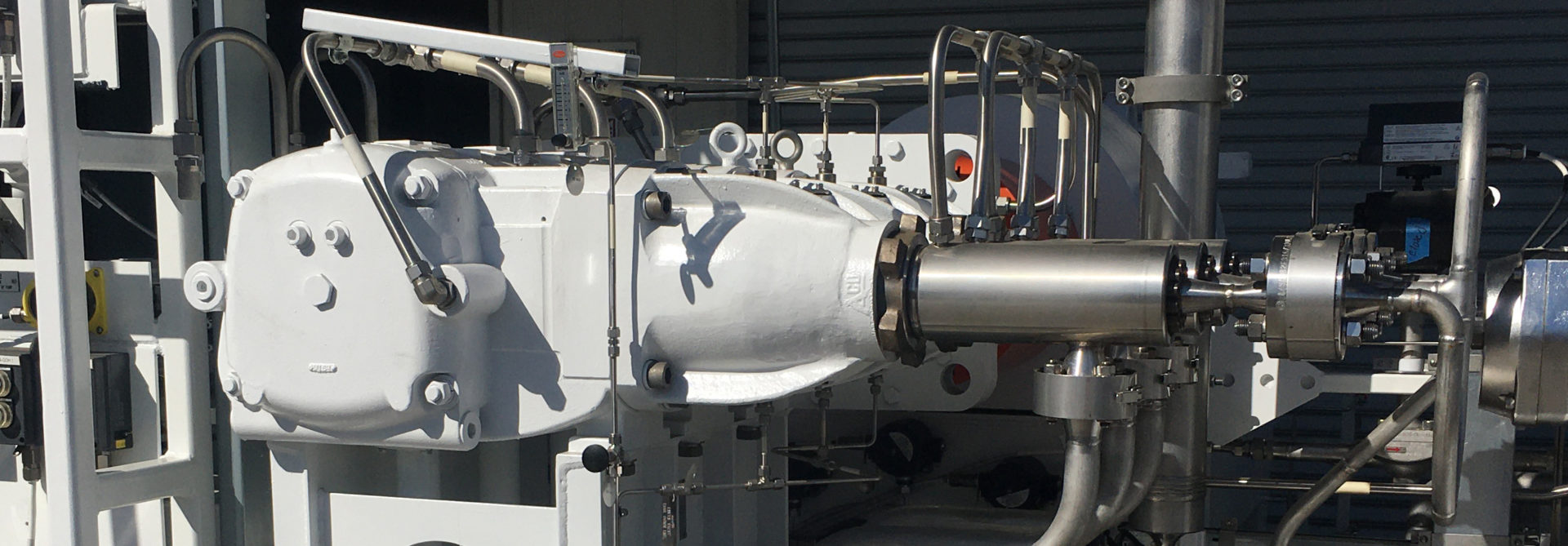

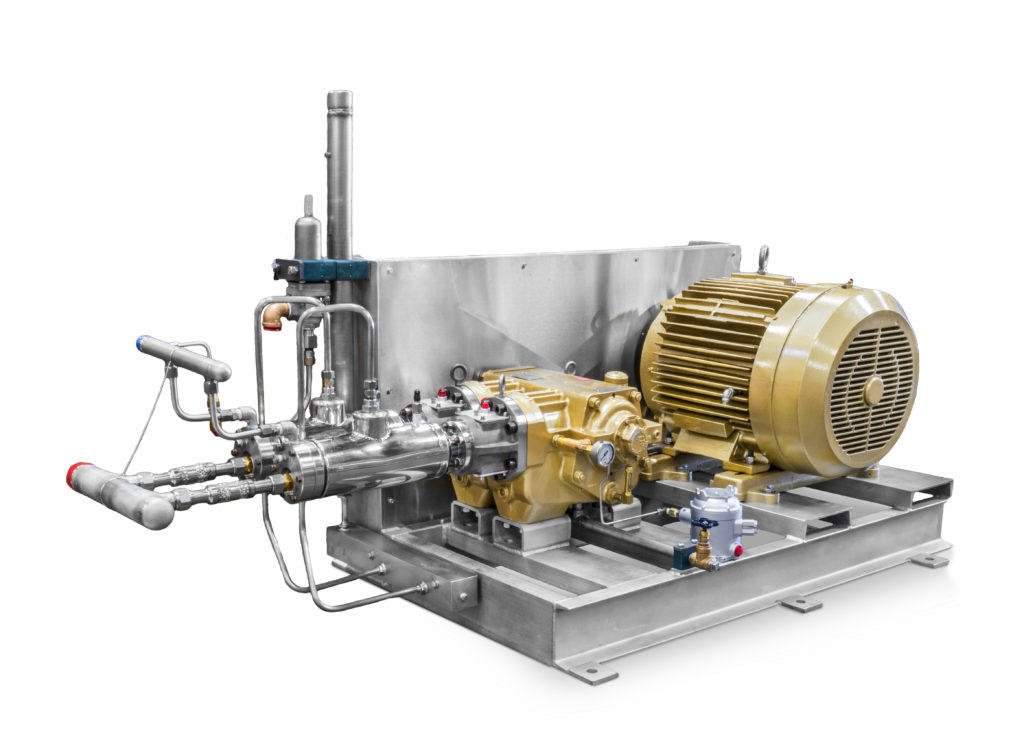

The SGV series is a modular, medium to heavy duty storage filling pump system available in 1, 2, or 3 cylinder configurations to provide a wide range of flows for any storage filling application. It has vacuum jacketed cold ends for minimal cool down losses and economical operation, especially beneficial in liquid hydrogen service. These cold ends are available in a variety of bore sizes so that the pump may be tailored to the flow and pressure requirement of a wide array of applications. The pump is driven by an electric motor through a heavy duty timing belt for maximum longevity. SGV pump skids are available on a retractable base allowing for simple and easy maintenance when connected to rigid vacuum jacketed piping. The drive has a robust self-contained pressurized forced oil lubrication system which is specifically designed to provide maximum drive life in heavy duty applications.

Features & Benefits

- Modular, compact displacement pumps available in 1, 2, or 3 cylinder configurations provide a wide range of flows

- Vacuum jacketed cold end for minimal cooldown losses and economical operation, ideal for liquid hydrogen

- Pressurized oil lubricated drive with integral oil pump and reservoir, allows higher bearing loads/prevent oil leakage

- Belt driven by electric drive motors allows for extended pump duty

- Improved cold end assembly design extends seal life

Applications

- Specially designed for storage filling

- LNG, LN2 and LH2 Process

- Special medium-to-heavy duty applications

- High Pressure Fuel Systems

Liquids Pumped

- Argon

- Hydrogen

- Methane

- Nitrogen

- Oxygen

Typical Scope of Supply

- Vacuum jacketed cold end with pressure oil lubricated drive end

- Positive locking coupling

- Standard suction adapter with Monel strainer

- Distance piece with purge ports

- Hot dipped galvanized steel skid

- TEFC motor

- High pressure relief valve with discharge line and surge chamber

- Drip pan kit (for LH2 only)

- Suction/vapor return manifold for multiple cylinders