Reciprocating Pumps

P2K

Overview

Description

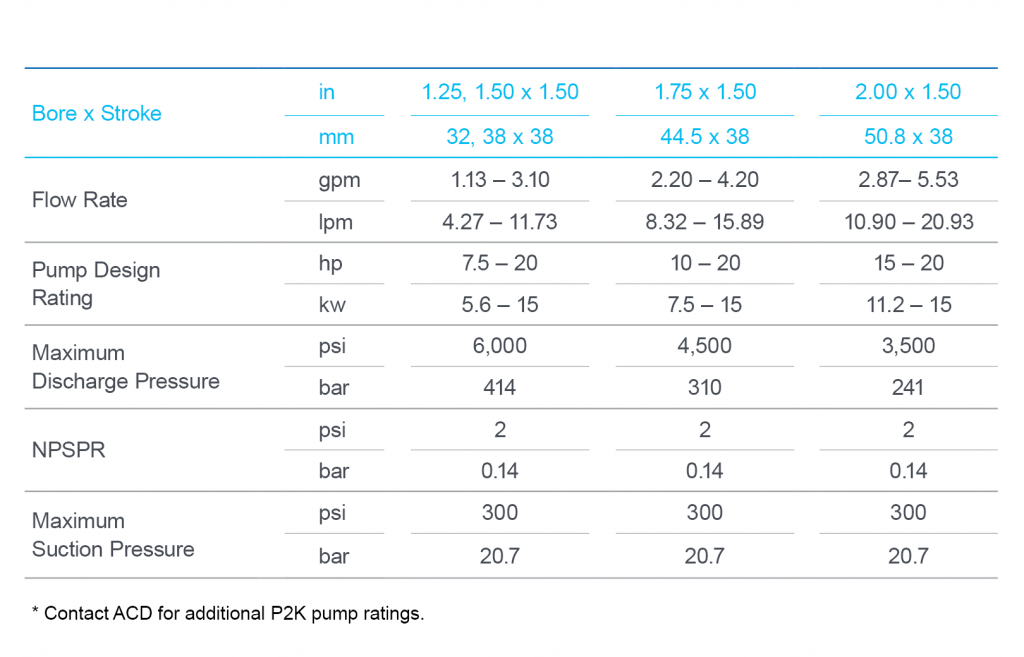

Specifications

[ paused ]

Fueling

Hydrogen

High Horsepower

Independent Gas Companies

End Users

Major Gas Companies

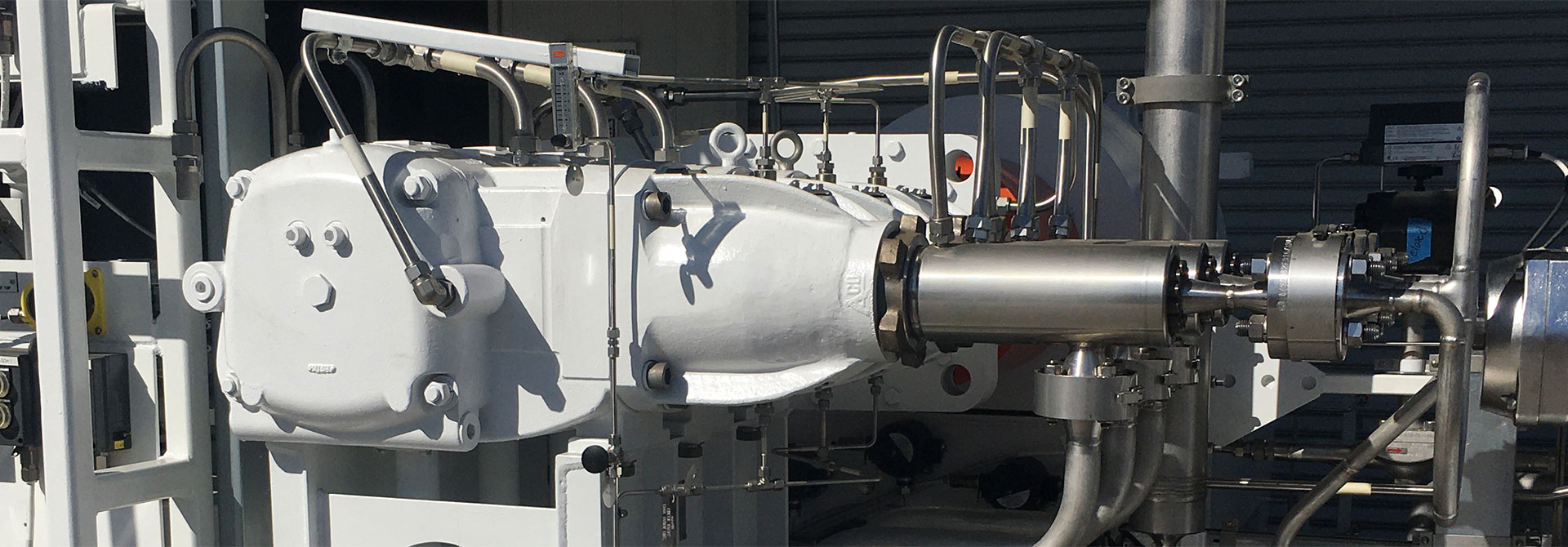

The P2K model is a vertical pump design that eliminates gravitational loading on the cold end piston, extending sealing ring life and providing smooth suction valve operation for ideal NPSPR characteristics. The vertical installation offers less vibration, reduced noise, and a compact system footprint. The vertical cold end is submerged inside a vacuum-jacketed sump, minimizing heat leak and increasing system efficiency (particularly in poor suction conditions). The sump is secured to the intermediate with a v-band clamp, allowing quick and easy access to the cold end assembly for maintenance.

Features & Benefits

- Vertical pump design eliminates gravitational loading on the piston, extending sealing ring life and providing smoother suction valve operation

- Vertical installation offers less vibration, reduced noise, and a compact system footprint

- V-band clamp secures the sump to the intermediate, allowing quick and easy access to the cold end assembly

- External re-lubrication nipples for roller bearings and crosshead provide an extended service life

- Replaceable crosshead wearband eliminates crosshead piston wear and reduces maintenance costs

- Packing rings at top of the pushrod are retained in cartridges for easy replacement (no removal of sump and cold end required)

- Motor positioned on the backside of the pumping skid eliminates possible fire, explosion, or hazard in the event of a liquid oxygen leak

- Vertical cold end is submerged inside a vacuum-jacketed liquid sump, minimizing heat leak and increasing system efficiency (particularly in poor suction conditions)

- Pump assembly and spare parts are interchangeable with the PD3000 pump

- Easy cold end maintenance by swiveling the pump and drive end 45°

Applications

- Heavy duty cylinder filling

- Medium duty storage filling

- Unattended, automatic storage filling

- Test Facility Support

Liquids Pumped

- Nitrogen

- Oxygen

- Argon

- Carbon Dioxide

- Ethylene

- Methane (LNG)

Typical Scope of Supply

- Flow rates from 1.13 GPM to 5.53 GPM (4.27 lpm to 20.93 lpm)

- Discharge pressures up to 6000 psig (414 barg)

- NPSPR of 2 psi or lower

- Intended for heavy duty cycles in cylinder filling applications and moderate duty cycles in storage filling applications