LINEX OL – Sacrificial Nitrogen Natural Gas Liquefier

Overview

Description

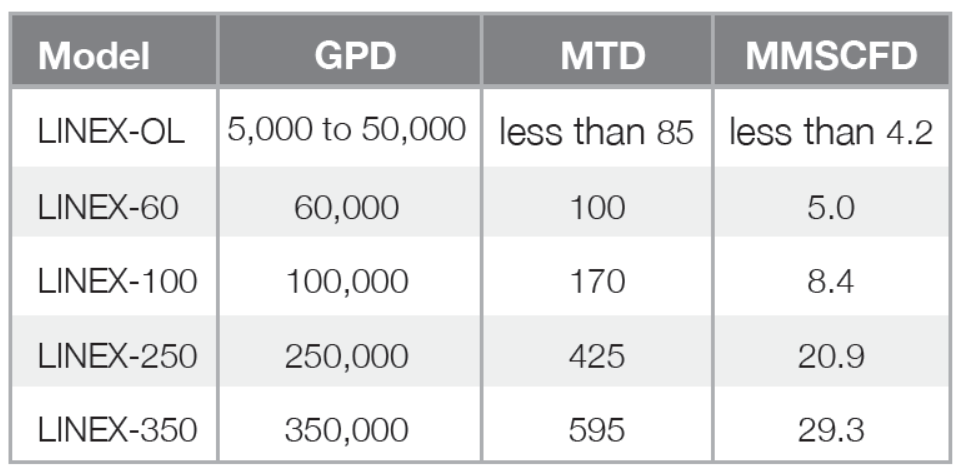

Specifications

Brochures & Resources

[ paused ]

Nikkiso Cosmodyne’s LINEX-OL series of natural gas liquefiers liquefy a clean stream of natural gas with a sacrificial source of liquid nitrogen as the refrigerant. This low capital, simple-to-operate approach to liquefaction is ideally suited for pilot projects where a market is to be tested. The plants are also well suited when the LNG capacity requirements is small, for BOG recondensing and for locations where power is not available.

Features & Benefits

- Expandable for growing with the market

- Unlimited turndown

- Inherent safety with inert, nonpolluting, corrosion-free nitrogen refrigerant

- Simple and rapid return to service after shutdown

- Reduced operator training and education requirements

- Operation easily adapts to changing feed gas composition

- Easily redeployed to another location

- Feed Gas Pretreatment (Water, Carbon Dioxide, Others)

- LNG Specification Matching

- Gas Stream Product Separation

- Trailer Loading Stations

- Many More Tailored to Customer Requirements

Applications

- Transportation / Distribution

- Peak shaving

- Virtual pipelines

Services

- On-site or in-factory operator training

- Installation and commissioning assistance

- Extended warranty package

- Service package

- Aftermarket spare parts support

- Aftermarket technical support

Cosmodyne LINEX OL Series

Cosmodyne LINEX OL Series Cosmodyne Closed Loop Natural Gas Liquefiers

Cosmodyne Closed Loop Natural Gas Liquefiers Cosmodyne - Choosing a profitable path

Cosmodyne - Choosing a profitable path Cosmodyne Pilot Programs and Open Loop

Cosmodyne Pilot Programs and Open Loop Cosmodyne Small Scale LNG

Cosmodyne Small Scale LNG 2014 SPRING Cosmodyne Pilot Programs and Open Loop Natural Gas Liquefiers

2014 SPRING Cosmodyne Pilot Programs and Open Loop Natural Gas Liquefiers