GFED Series

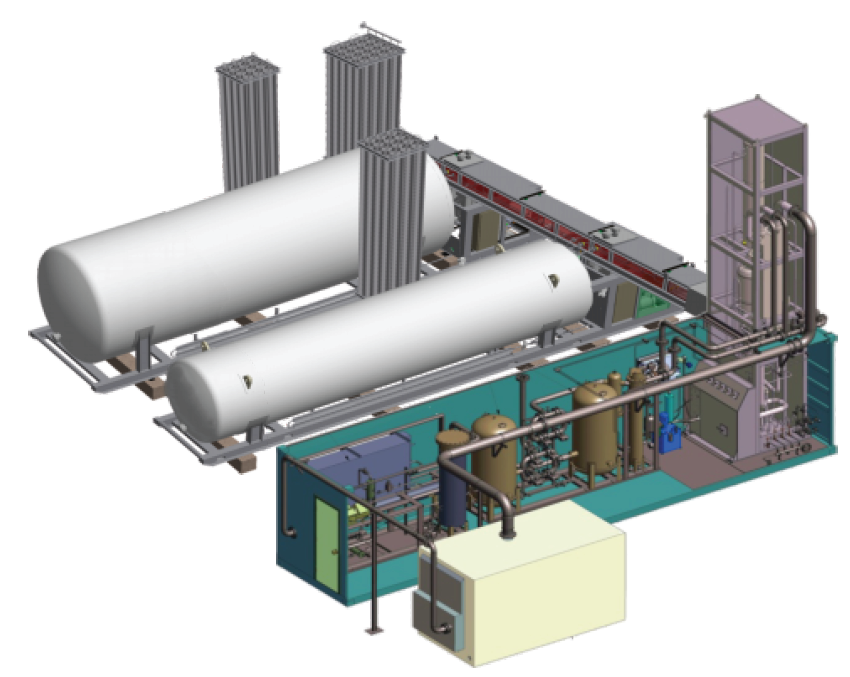

The GFED is a small air separation plant that produces liquid Oxygen and liquid Nitrogen by cryogenic distillation of cryogenic air. Capacities range from 4 to 7 metric tons per day.

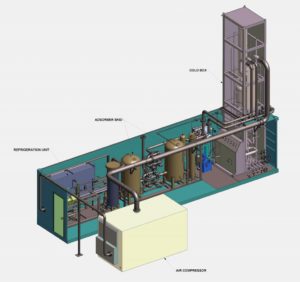

The GFED is designed to minimize shipping and allow for rapid installation by providing the plant in three distinct pre-piped and pre-wired modules: the main air compressor, the warm end module and the cold box.

All of the machinery is designed to be air-cooled so a source of low voltage power is the only required utility. The plant systems are self-contained and can be completely installed outdoors, requiring only a simple foundation.

The entire plant ships in two 40-foot shipping containers.

The GFED plants are designed to meet the most severe operating conditions.

Over 50 GFED plants are currently producing liquid oxygen and nitrogen for medical, industrial, oil field and military applications in some of the most remote regions of the world.

Features & Benefits

- High-performance ACD hydrodynamic bearing Turboexpander

- Cartridge-style rotating element Turboexpander

- Efficient, reliable oil free; centrifugal or dry screw air compressor

- Proven TSA air pre-purification system

- Choice of 50 or 60 Hz power systems

- Ships as two standard ISO containers to minimize transportation expense

- Complete with all interconnecting piping and electrical systems, ready for installation

- CE compliance

- Fully automatic digital process-control system with “touch-screen” operator interface

- Air cooled, evaporative water cooled or dry glycol cooling tower cooled

- Integrated cylinder filling system

- Integrated product storage system

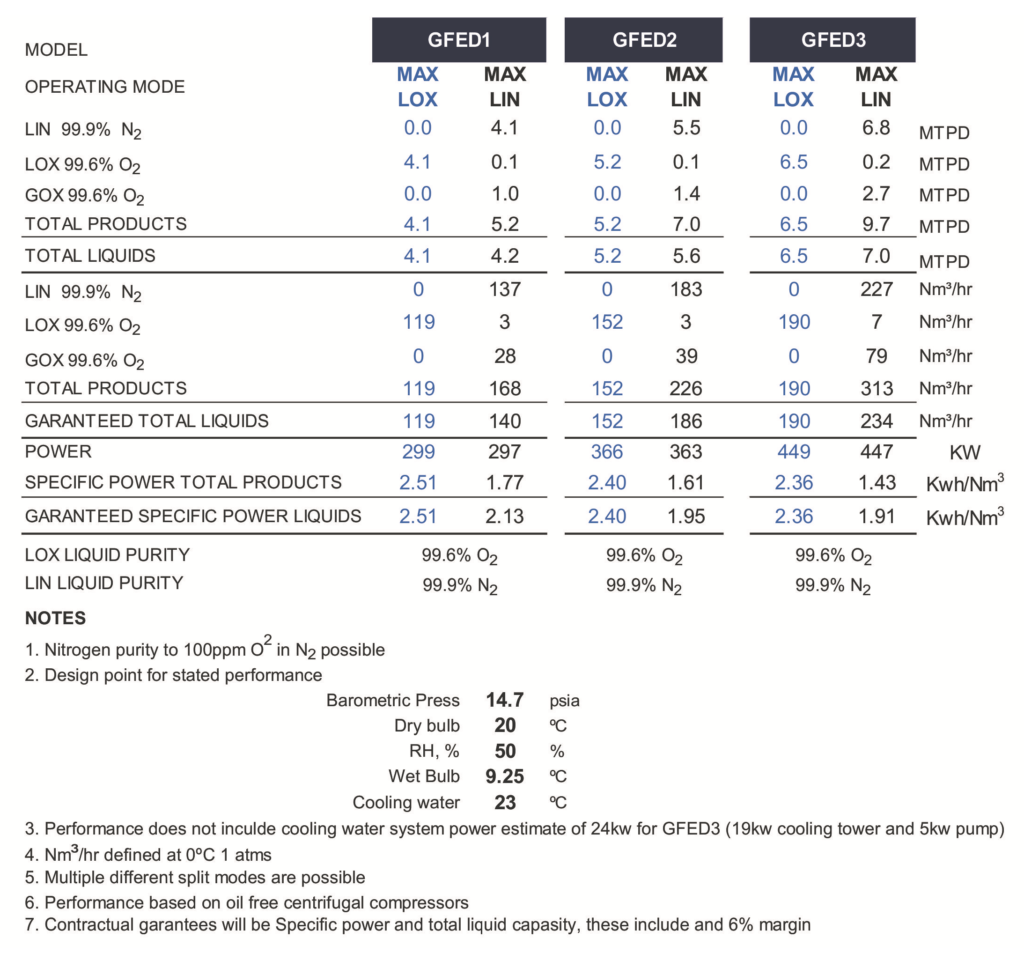

Specifications

GFED Performance Table

Click on table to open in a new window.

Options and Accessories

- CE compliance

- Fully automatic digital process-control system with “touch-screen” operator interface

- Air cooled, evaporative water cooled or dry glycol cooling tower cooled

- Integrated cylinder filling system

- Integrated product storage system

Cosmodyne GFED Series

Cosmodyne GFED Series GFED Series plants offer portability and low installation cost

GFED Series plants offer portability and low installation cost Purchasing small to medium size merchant air separation plants

Purchasing small to medium size merchant air separation plants GFED Farm Tank and Options

GFED Farm Tank and Options