Onsite Gas Generation Plants

TGN - Self Refrigerated

Independent Gas Companies

End Users

Gas Recovery

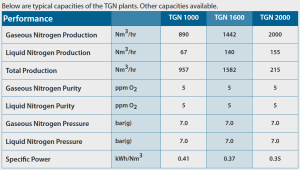

The TGN series plants produce high gaseous nitrogen by cryogenic distillation of atmospheric air. In addition, they also produce a small amount of liquid nitrogen to store for peaking or back-up purposes. The TGN series plants are efficient, reliable, and compact.

The TGN series plant utilizes a waste gas expansion cycle using a Turboexpander to produce gaseous and liquid nitrogen. The layout is configured to provide maximum efficiency and ease of maintenance. The plant consists of three modules, an Air Compressor Module (ACM) that provides process air, a Warm Equipment Module (WEM) that purifies compressed air and a Cold Box Module (CBM) that houses the distillation equipment. These modules are pre-wired and pre-piped for ease of installation.

Features & Benefits

- Automatic process control

- Designed for unattended operation

- Once the plant is started and running, the air separation process, purity control and all the subsystems external to cold box are fully automatic.

- Nikkiso Cosmodyne PLC based control system provides efficient, user-friendly graphic interface for remote, local or unattended operation

- Automatic control of all primary plant functions

- State-of-the-art analytical instrumentation package

- Dual, high performance turboexpanders with removable cartridge style rotating elements

- Proven molecular sieve type air clean-up system

- Closed Loop Evaporative Cooling System

- 50 or 60 Hertz Electrical System

- Product Storage Tanks

- Cylinder Charging Systems

- Liquid Transfer Pump Systems

- Other customized features for site specific requirements

Applications

- Emerging Markets

- Remote Locations

- Medical

- Industrial

- Oil Field

- Military

- Metal Processing

- Glass

- Food

Services

- On-site or in-factory operator training

- Installation and commissioning assistance

- Extended warranty package

- Service package

- Aftermarket spare parts support

- Aftermarket technical support