All Brand Support

All Brand Support

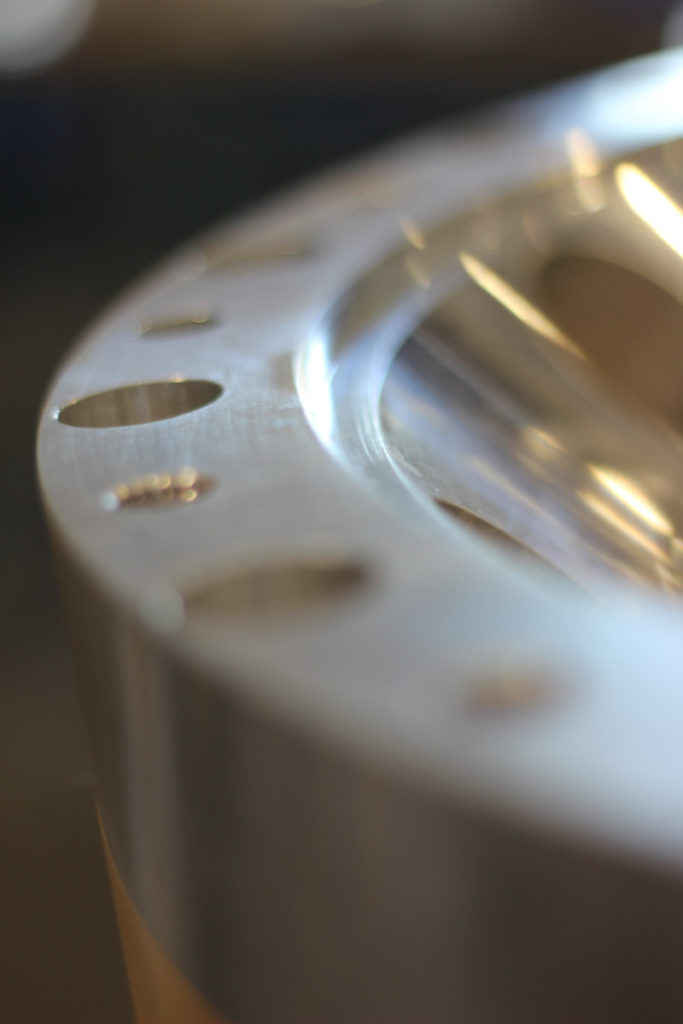

Nikkiso Cryogenic Industries Service supports a full range of turbo machine parts and services.

In addition to Nikkiso products we specialize in repairing all cryogenic pumps and Turboexpander equipment including cryogenic centrifugal and reciprocating pumps and equipment manufactured by J.C. Carter, CVI, Cryomach, CCI, Cosmodyne, CS&P, and Cryostar. NCS can supply all spare parts including wheels, inlet guide vanes, bearings and other components for expanders that are no longer being effectively serviced by OEMs. NCS will provide any and all services timely and reliably by the NCS team of field service technicians.

With over 15,000 pumps and 1,200 Turboexpanders installed globally and over 75 field service technicians, NCS provides 65 years of expertise and know-how on repair parts and equipment servicing. Service is provided from our base of 18 global locations, reaching nearly 200 countries, supporting cryogenic equipment and Turboexpanders.

Pumps

- ACD

- Nikkiso Cryo

- Cosmodyne

- ACD Cryo

- J.C. Carter

- CVI

- Cryomach

- CCI

- CS&P

- Cryostar

- Vanzetti

- MAN

Turbos

- Air Liquide

- Atlas Copco

- Rotoflow

- Cryostar

- Texas Turbine

- LA Turbine

Features & Benefits

- Service from 18 global locations, reaching 200 countries

- 75 field service technicians

- ISO 9001-2015 certified

- Full machining capabilities

- Comprehensive Diagnostics

- 24/7 customer support from certified technicians.

- Long Term Service Agreements

Cosmodyne

Cryogenic Process Systems Plant Services

With over 60 years of experience designing and building cryogenic process plants, Nikkiso Cryogenic Industries Service companies can add value to your plant assets with services that maximize the investment return from your Air Separation Plant or Natural Gas Liquefier.Services Offered

- Process Performance/Efficiency Evaluation and Optimization

- Debottlenecking

- Equipment Upgrades – NG pretreatment – Cooling systems – Compressors – Liquefiers/turboexpanders

- Control Systems Upgrades

- OPEX Reduction

- Operator Training

- On Site Services

- Remote troubleshooting and training reinforcement

Expertise

- Cryogenic Air Separation Plants

- Oxygen and Nitrogen Liquefiers

- Natural Gas Liquefiers

- Argon Recovery

- Nitrogen Expander Refrigeration Cycles

- Single Mixed Refrigerant (SMR) Refrigerant Cycles

- Amine wash and Molecular Sieves Adsorption system

- Natural Gas Treatment Systems

- Hydrocarbon Separation

- Nitrogen Rejection Units for Natural Gas

- Boil Off Gas Management Systems

- Turboexpanders

We value the relationships that we have built for over 60 years in the industry and we are committed to ensuring that our customers are satisfied with their cryogenic equipment, whether it is a Nikkiso product or not. Our experts will work with your team to evaluate your challenge and provide solutions to repair, replace or improve your processes. Our company has provided quality support dating back to the early Apollo missions, and we continue to serve industries such as Aerospace, Utilities, LNG Merchants, Major Industrial Gas Suppliers, and Owner Operated Industrial gas plants.

Cryoquip

Heat Exchanger Systems

A global leader in the engineered solutions and fabrication of cryogenic vaporizers and industrial gas equipment. Our capabilities span from cold boxes used to produce liquefied gases to the equipment that stores and vaporizes them. Nikkiso Cryoquip has over 50 years’ experience in the industry, providing technical expertise and factory support to our full line of engineered Heat Exchanger systems.Scheduled Tuning Service

Whether used as a back up to an industrial gas pipeline, power generation fueling, primary process or peak shaving vaporizer, providing scheduled tuning and factory support of Gas Fired Water Bath Vaporizers can help ensure your unit is meeting emissions requirements and performance.Field Evaluations

Cryogenic vaporizers are critical to operations requiring minimal to zero downtime, whether for back up supply or primary process vaporization. Age and operating conditions may require inspection and product support. We offer evaluations of in-service vaporizers, providing multipoint inspections to address issues before they become a problem – minimizing downtime and costs.Equipment Training – Educational Services

Learn more about the proper installation and operation of Nikkiso Cryoquip products and equipment through our customized training courses covering:- Ambient Vaporizers

- Natural Gas Fired Vaporizers

- SF6 Equipment

- Steam Heated Vaporizers

Field Service

Nikkiso’s team of engineers, factory trained technicians and network support staff are available to help with:- Burner tuning

- Preventive Maintenance

- Equipment Troubleshooting

- Start-Up and Commissioning

- Service Plans and Repairs

- … and more