Industrial Nitrogen Liquefier

Nitrogen Liquifiers provide sub-cooled liquid nitrogen from gaseous nitrogen feed gas for the many applications that use liquid nitrogen. Our Nitrogen Liquifiers are designed to provide you with liquid nitrogen from any clean and dry gaseous nitrogen source, typically from the overhead nitrogen stream from an air separation plant (ASU) that would otherwise be vented. Whatever your application or industry, our nitrogen liquifiers have the versatility needed to adapt to your specific needs, such as liquefying an oxygen gas stream or simultaneous liquefaction of oxygen and nitrogen gas streams.

At Cosmodyne, we leverage a combination of industry expertise and a versatile array of options to provide the ideal solution for nearly any facility. Our modular Nitrogen Liquefaction Plants can be configured to carry out whatever task is needed.

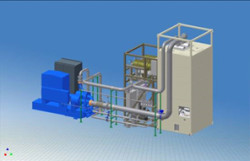

For small, medium- and large-scale industrial liquid nitrogen needs, our ELM Series Nitrogen Liquefier is one of the most efficient, reliable, and cost-effective solutions available to debottleneck an air separation plant. The ELM Series Liquefier features a modular design that can be tailored to fit your facility’s specific needs. Flow rate, pressure, and purity level are all completely adjustable depending on what you require. This unit is equipped with single or, if need be for efficiency purposes, dual Cosmodyne turboexpanders (> 500 Nm³/hr).

ELM Series Liquifier

Using a feed gas supply and a refrigeration cycle in which nitrogen is compressed above the critical pressure and then expanded through one or two turboexpanders, our powerful, efficient ELM Series Liquefier produces sub-cooled liquid nitrogen and/or oxygen from a clean and dry feed gas supply. Like most of our other products, the ELM nitrogen liquefier utilizes our Cosmodyne PLC-based control system, which gives users access to a user-friendly graphic interface and enables remote, local, or even unattended operation.

With a broad production range of 150 to 10,000 Nm³/hr., the ELM Series has a level of versatility that enables its use in a wide variety of industrial contexts. The liquefier can take a clean and dry gas stream from most any feed source, including but not limited to air separation plants or non-cryogenic gas generators, to produce the liquid products.

Additionally, our ELM plant is designed to minimize shipping costs and allow for rapid installation by delivering the plant in distinct pre-piped, pre-wired mod

ules.

ules.

Nitrogen Liquifiers Designed to Fit Your Needs

Our industrial nitrogen liquefier gives you access to the level and quality of liquid nitrogen needed to carry out your facility-specific purposes, regardless of technical requirements. With Cosmodyne’s plants, your supply of liquid nitrogen will be created at the correct flow rate, purity, and pressure.

When you select a Cosmodyne plant, you aren’t just acquiring to an industry-leading solution, you are gaining access to a professional team with a wealth of experience, high-quality, readily available parts and service, and both onsite and remote assistance and support throughout installation and start-up.

Experienced Global Service

As demand for liquid nitrogen increases, Cosmodyne provides everything needed to operate your air separation and nitrogen liquefier with a high efficiency rate. Through our service and support, we can help provide you with the tools you need to meet and even exceed your operational goals. We offer support in our service centers, with locations all over the world, making in-person support accessible and convenient.

We staff our Customer Service Department with seasoned professionals that have years of technical experience in a wide array of different fields in order to give you access to comprehensive expertise. Whether you have a problem or you just want more information on any given facet of your plant, Cosmodyne gives you the support you need to keep your nitrogen liquefier operating the way that it should.

If a more significant problem arises or if you’d prefer hands-on support, our team of onsite care professionals can provide you with the experience needed to resolve any difficulty. This team is well-versed in multiple industrial applications of nitrogen liquifiers, and will work with you throughout the processes of regular maintenance, instrument calibration, and equipment performance optimization. If you require further assistance, Cosmodyne provides a controls package that gives you direct access to our experienced global technicians and engineers using remote access, further simplifying the troubleshooting process. With our expert care and support, you can be sure that your nitrogen liquefier will perform efficiently.

Through our onsite care, helpful customer service department, and remote assistance, Cosmodyne helps you address any and all challenges you might face with your nitrogen liquefier, ensuring that your plant and facility operate as they should.